Energy

Transforming wind energy construction and maintenance

Wind Energy has a problem;

More cranes are needed.

There simply are not enough land and sea cranes to build the forecasted new wind farms and then maintain them. And they need to have higher hook heights, cost less, and work faster!

They need to be taller. cost less. work faster.

SkyLifters are a family of three payload sizes

scaling from 2 to 250 tonnes, SkyLifters offer multi-role versatility

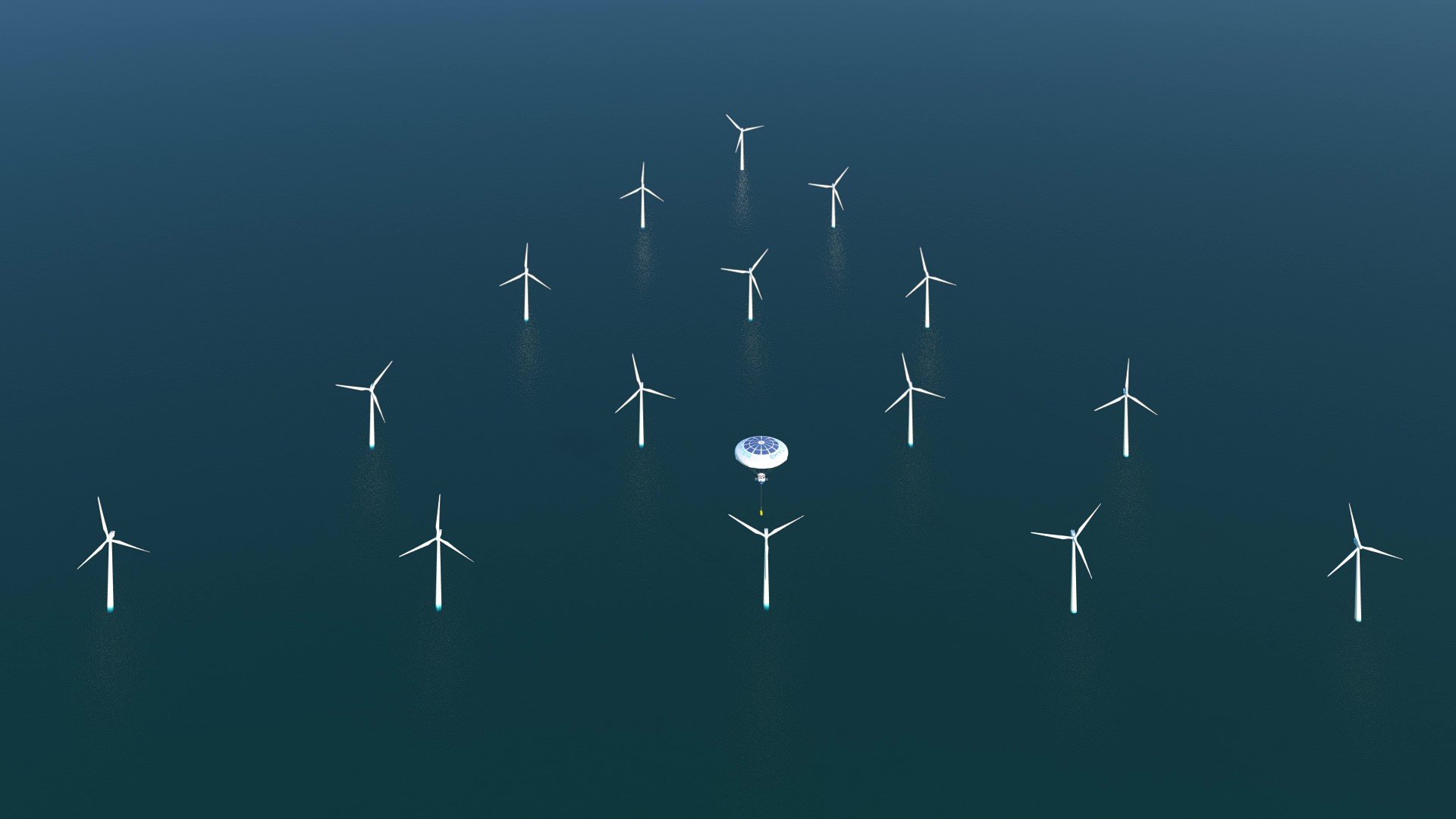

SkyLifters offer multi-role versatility as highly mobile air-cranes with unlimited hook heights and the geo-stationary precision needed to satisfy rigging operations.

For offshore wind, Main Component Replacement (MCR) is a major problem, particularly for floating offshore turbines. Using ship cranes is prohibitively expensive and slow. SkyLifters will carry out MCR by directly lifting the old offshore turbine components from the nacelle, flying them to shore and returning with replacements, with precision for installation. Studies have shown that using SkyLifters is 7x faster and 12x less expensive than using ship cranes. SkyLifters can also be half the cost of using jack-up sea-cranes.

-

Crew & Resupply

-

Lift, anywhere

-

Logistics, anywhere

enabling maintenance crews to move more rapidly between wind farms

SkyLifters may supersede ship cranes, jack ups and their support vessels

Another scenario could see the smaller SkyLifters deliver more capability than helicopters, and for less cost. SkyLifters’ wider weather window and independence from the sea surface condition could enable more frequent re-supply runs to offshore platforms, with larger payloads, and done with no polluting emissions or noise impact on marine life.